STAGES

Stage 1

Stage 2

Stage 3

Stage 1 - Pool Design Concept and Hydraulic Specification

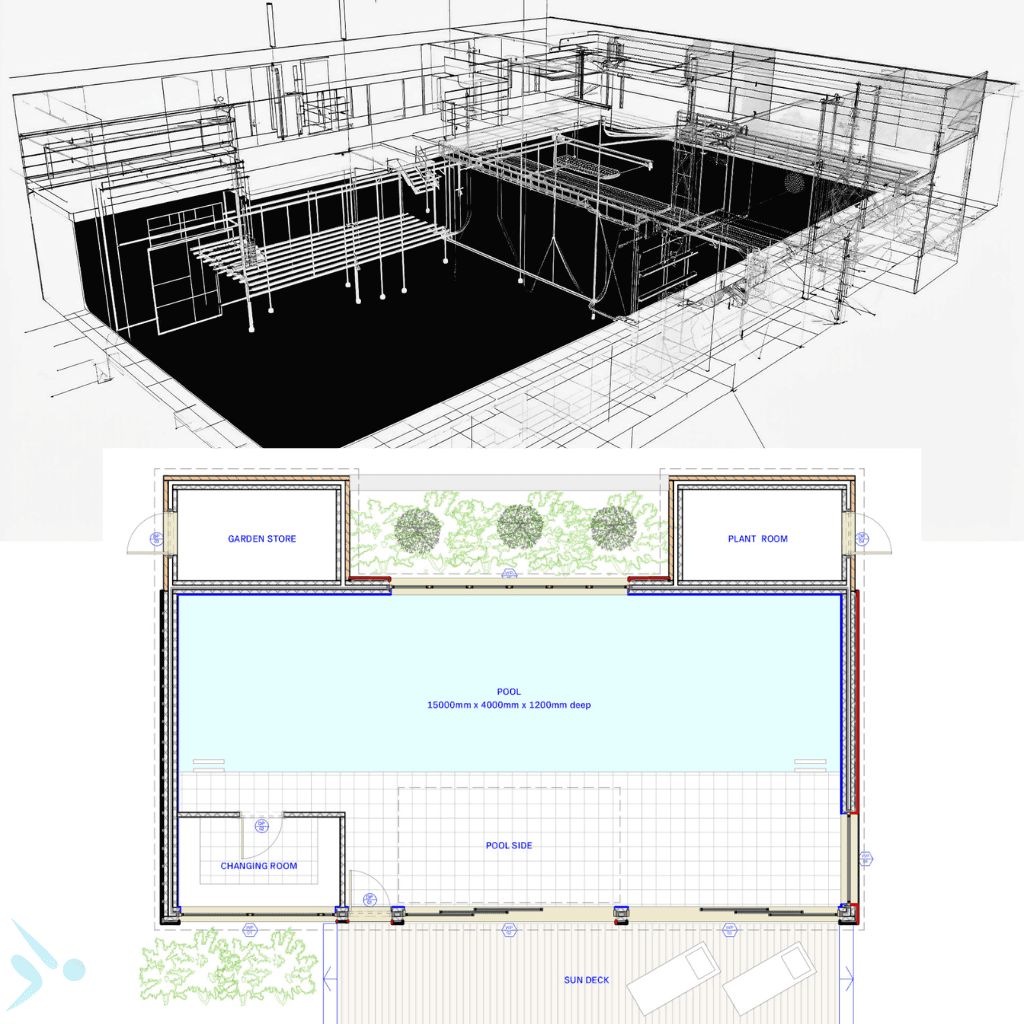

At Luxpool UK, we create set strategies to completely understand the client’s vision through a collaborative and comprehensive design approach. We have an in-house team of specialist pool designers who understand the pool technical and hydraulics methodology that suits your project requirements and your budget. Our design aims to deliver high-quality and effective solutions that are bespoke to your project. Our specifications are fully detailed and as per the latest regulations, reflecting a sustainable and hybrid approach.

We offer a complete 2D and 3D design with renders to maximise the project clarity, this allows you to experience your finished design before the commencement of construction. We use the latest tools and software like AutoCAD TRR, Revit, Teckla, Lumion, and 3D Max. We provide a detailed cost breakdown from the initial phase to completion, highlighting the project build process, groundworks, structure, finishes, waterproofing, and mechanical and electrical hydraulics.

Stage 2 - Pool Construction & Development Process

1️⃣ Ground Testing & Structural Frame – Site survey, excavation, and RCC steel framework installation.

2️⃣ RCC Marine Grade Structure & M&E First Fix – Corrosion-resistant steel reinforcement, pipework, and lighting setup.

3️⃣ Curing & Installations – Concrete curing, filtration, and essential fittings installed.

4️⃣ Waterproofing & Tiling – HDPE membrane, ARDEX coatings, leak tests, and tile installation.

5️⃣ HVAC (Indoor Pools) – Heat & ventilation system for efficient climate control.

6️⃣ AFM Filtration & Chemical-Free Dosing – Chlorine-free system providing drinking-quality water.

7️⃣ Water Treatment & Discharge – Daisy Plus system enables safe drainage without storage tanks.

This process ensures a durable, eco-friendly, and high-quality pool construction.

1. Ground Testing / Excavation / Structural Frame

The first step is to determine the ground conditions. Our ground hydraulics engineer surveys the site prior to commencing any work on site. Upon completion of the survey, the results are reflected in the pool design, pool methodology and construction method statement including RAMS. Once all the results are satisfied, we initiate the site construction process. Excavation is carried out in sections to avoid lateral forces including gravitational shoring. Side walls are supported through injection plates and a pool shell base is formed. The coordinates are set to the exact dimensions marked on the drawings. The RCC steel is caged as per structural specifications.

2. RCC FBE Marine grade Structure & Sika Concrete and 1st Fix M&E

The RCC steel frame is set up with all the reinforcement bars. Steel shuttering is placed up to bolster pools as per level indicated to FFL. Based on accurate structural steel measurements, FBE Fusion bonded epoxy-coated rebars are laid as per drawings. We use special steel rebars known as FBE for pool shells as it offer high stability and resistance to corrosion and chemicals in the environment. The structure is treated as a marine grade as it is best at resisting corrosion, high water table fluctuation, and silt conditions, hence increasing the service life of structure. Upon completion of the steel frame, the first fix M&E is carried out, which includes adding all the pipe work and lighting castings in stainless steel or uPVC. We recommend using stainless steel due to its variable compression strength. Upon completion of the M&E first fix, we move to concreting the entire structure. Sika waterproof concrete is used. There are various methods we use depending on the environmental condition cure setting time and ground stability. The types of pouring that are most efficient for durability are either concrete pump with a blast no longer than 20 seconds shot or shotcrete dry spray with 65 to 80 velocity per M CFM(425 m3/h). Sika WT-200 offers high durability, self-healing, water penetration resistance, chemical resistance, waterproofing, reduced vapor transmission, and mold resistance. The mix of steel and concrete forms a rigid marine-grade system that comes with more than 15 years of guarantee.

3. Curing and Installations

The shell usually takes between 4 days to cure with the initial setting time for wet conditions being 8-10 hours and the final setting time of 48 to 72 hours. This mainly depends on multiple factors including the size, complexity of the pool, weather and ground conditions. Whilst the shell cures we work on remaining pipe works and hydraulics to plant room. The castings are statically tested including the joints for any penetration movement. The fittings are fixed including but not limited to. - SS Castings - Pipe connections ½ & 2/3 - Sumps - Vacuum suction fittings - Skimmers SS or colored - Return water inlets - Advanced filtration systems AFM - Color-changing LED lighting - Dosing media - Variable pump - Digital controller - Pool Cover castings

4. Waterproof Sealing and Tiling

Upon completion of the concrete, we move to the next step by adding an extra layer of protection to the structure and making it watertight. The frame is coated with an ultra-high-performance HDPE (High-Density Polyethylene) membrane for a waterproof, fully bonded barrier. An ARDEX S7 & A38 is used. This is the best product as it consists of fine fiber reinforcement which can resist water pressure up to 5 bar along with excellent slump resistance. A tanking coating system is used before the ceramic tiles are fixed. We do a drop test and water static test to verify that there are no leaks and then the pool sits for drying before we install the final fixtures and tiles. We offer a large variety of tiles, including traditional blue mosaics, porcelain, glass, stone and custom-made designs. Our tilers are experts in laying all types of tiles in various designs and shapes. For traditional or custom designs, we work with the leading tile manufacturers to offer the best vision for your project.

5. HVAC Heating and Ventilation – Applicable for Indoor Pools

After the tile is laid, we start setting up the heat and ventilation system. We offer the best HAVC sustain system that offers a sustainable approach to maintaining the pool room air quality, hybrid use of heat system, with reduced evaporation. We use the Heatstar system as this is one of the best systems that is hybrid and offers reduced energy costs in the long run. The configuration is mainly depending on pool size and shape. Following this ventilation ducts are installed and insulated to avoid any condensation. They are installed either in the ceiling or underneath the floor.

6. AFM Filtration and Dosing System and final Fix M&E - DRINKING QUALITY WATER

There are many filter media and dosing systems in the market that use chlorine and other chemicals to keep the pool water clear. However, most of the system uses chlorine, which is not good for human skin. The chlorine and other toxic chemicals absorb through your skin and cause rashes, eye irritation, asthma and other skin conditions. We offer the best chlorine/chemical-free filtration/dosing (electrolysis) systems that keep the pool water crystal clear and suitable for drinking. We assure you clear, unpolluted, chemical-free water so that you can enjoy your swimming with pleasure.

7. Water Treatment / Water Disinfection prior to draining into the drain

Under the water treatment and sewerage regulation every pool water at its interval needs to be treated before draining to public sewer. However, with the Daisy Plus system, we don’t need to treat or disinfect water or use any storage tank or septic tank. The water is discharged straight into the drain as the chlorine level is lower than the drinking tap water. • We would need a septic tank to treat water (disinfection) if the chlorine (salt) level is 2.5 – 3.5g/l • Normal chlorine level with a normal filtration system is between 2.5 – 3.5 g/l • Only electrolysis with the Daisy plus system can reduce it to 0.5g/l which is drink quality water and below the tap water which is 0.6g/l (recommended where people have skin allergies or sensitive conditions) The purpose of using of storage tank is to retain the water for at least a week so the chlorine within the water can kill the bacteria developed within the tank due to storage for more than a week. Storage tank or septic tanks are used where the chlorine level from the pool is above 0.7 – 2.5 g/l. By storing water prior to draining into the drain, the pool water must be treated and disinfected, in this process the bacteria and chlorine fights together and reduces the effect of chlorine due to being used to kill bacteria and following that it is safe to drain. The process is compulsory on all systems other than Daisy Plus. Also, septic tanks are strictly compulsory in commercial pools due to regulations. Note: There is always chlorine in water which is added by seven Trent or water providers to kill bacteria. And it measures to 0.6 g/l approx.

Stage 3 - Final Testing, Commissioning and Handover

The final stage is to test and commission the pool system. Note – The system is only going to be hybrid efficient and will only draw required volume (without loss) if the end to end flow is balanced.

Improving pool circulation and eliminating Dead Spots

As a rule of thumb, the layout should be designed in a way that prevents any dead spots within the pool area, offering end-to-end flow.

For Skimmer Type:

- Inlets should be on the shallow end wall, skimmers to be on the deep end wall with both sumps to be in the deep end.

For Overflow Type:

- The inlets in the wall directing water up at an angle to over flow channel. Sumps are to be laid evenly over the length of the pool.

FAQ

What is the purpose of your design consultancy service?

Our design consultancy service is aimed at turning your pool vision into reality. We provide expert advice and tailored solutions to create a pool design that aligns with your lifestyle, preferences, and site requirements.

How do you ensure the pool design meets my expectations?

We collaborate with you throughout the design process, discussing your ideas and providing innovative solutions. Our focus is on creating a pool that balances aesthetics, functionality, and compliance with technical and regulatory standards.

What does the design development process involve?

Design development involves refining the initial concept through detailed technical drawings and 3D visualizations. During this stage, we finalize the materials, finishes, and structural components to ensure the design is ready for construction.

Can you integrate the pool design with my existing outdoor space?

Yes, we carefully plan each design to harmonize with your outdoor environment, ensuring a seamless integration that enhances the overall appeal and functionality of your property.

What is performance specification, and why is it important?

Performance specification defines the standards for constructing and operating your pool, including safety, efficiency, and durability. It ensures that every component of your pool meets rigorous quality benchmarks for long-term performance.

What systems and components are covered in the performance specification?

Our specifications cover essential systems like filtration, waterproofing, mechanical equipment, and structural elements, ensuring your pool operates efficiently and safely.

How do you ensure the quality of the pool during construction?

We conduct regular checks and compliance assessments throughout the construction process. This guarantees that the pool is built to the highest standards, meeting all outlined specifications.

Why should I choose your company for my swimming pool project?

With expertise in design, development, and performance, we provide a comprehensive approach to creating pools that combine beauty, functionality, and long-term durability. Our attention to detail ensures you receive a pool that exceeds your expectations.