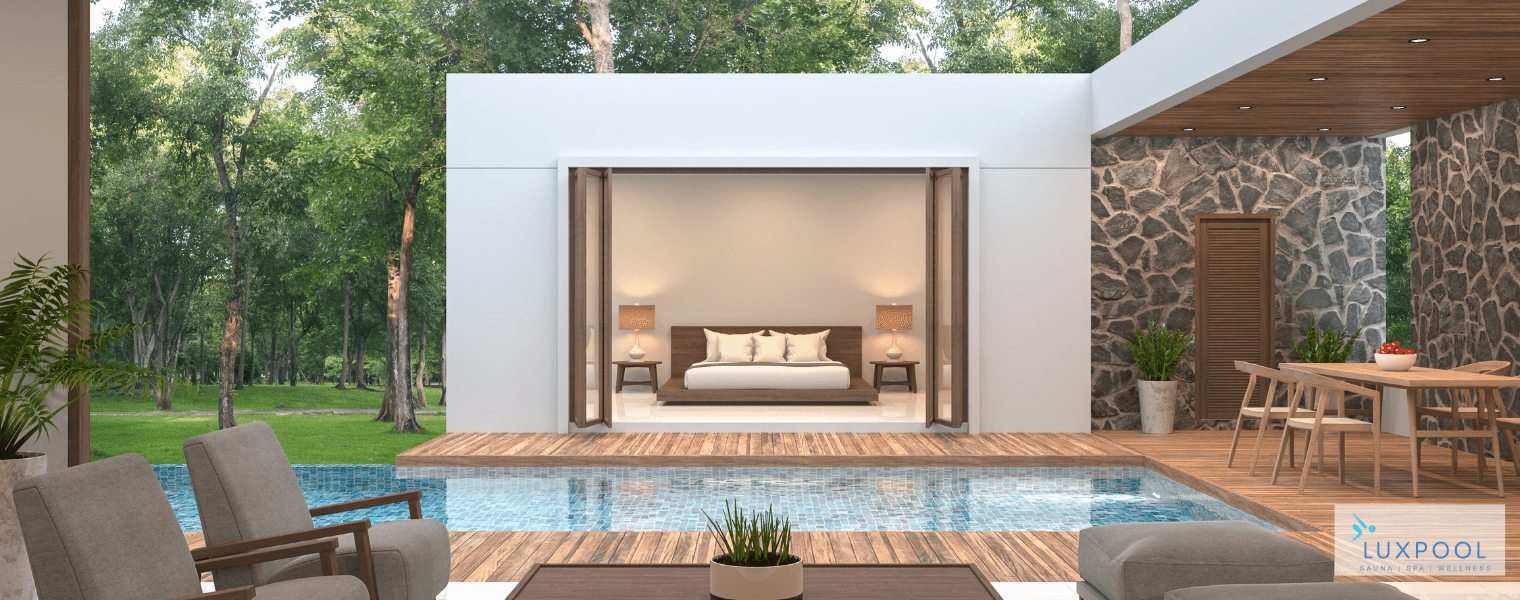

The indoor and basement swimming pools are a symbol of luxury and well being yet they present one silent challenge that can silently lead to the destruction of a building structure, toxic air, and expensive maintenance unless its condensation is controlled.

Luxpool, experts in swimming pool design and construction in the UK and UAE have created the definitive guide to pool condensation and humidity management in an indoor swimming pool environment. What are the causes and what will be the prevention, and the use of modern dehumidification, ventilation, and design methods.

What Is Condensation in an Indoor Pool?

When hot, damp air is in contact with a cooler surface, condensation takes place. The wetness of the air at the time transforms into a water droplet similar to fogging a cold window.

The persistence of the evaporation of the surface of a swimming pool on an indoor or a basement swimming pool room is very high thus making it very humid. This moist air condenses when it comes into contact with any material which is below its dew point (which is typically glass, concrete, or metal).

In the long run, this causes mould, corrosion, peeling of the paint, structural deterioration, and unfavourable indoor climate.

Why Indoor Pools in the UK are so Exposed

The tight insulation and the little ventilation that is done in the UK homes are usually meant to dominate the heat which is a great way of conserving energy but not handling moisture.

Massive pools of water vapour are generated by indoor and basement pools, steam rooms and saunas. In the absence of special humidity control devices, the condensation is easily accumulated, particularly in the colder seasons when the indoor and outdoor temperatures vary widely.

Typical UK challenges are:

- External walls and glazing in winter are colder, and this raises the risk of condensation.

- Poorly ventilated underground or basement pools.

- Retrofit projects in which the humidity was not initially planned to be controlled in pool rooms.

- Homes that are airtight and energy efficient, but poorly controlled with regard to moisture.

Learning Physics: Dew Point, Humidity and Evaporation

In order to control the condensation process, it is beneficial to learn the science behind condensation.

Relative Humidity (RH)

This is the mass of vapour water in the air relative to the highest mass that it is capable of containing at this temperature.

Ideal indoor pool RH: 50%-60%

Above 65%: condensation, mould and discomfort begin to grow.

Below 45%: evaporation increases, consuming energy and drying furnishings.

Dew Point

The temperature at which the moisture condenses out of the air.

When the air of a pool room (30°C) contacts a surface, which is 20°C, the dew point can be met and condensation occurs.

Evaporation Rate

Evaporation depends on:

Water temperature (low temp- less vapour)

Air temperature (cooler air contains less moisture

Air circulation (drafts or fans augment evaporation)

Surface area and activity of the pool (swimming, bubbling spa jets generate more vapours)

The way Condensation Destroys the Structures of Indoor Pools

An uncontrolled condensation will also ruin an indoor pool environment by passing silently, over a period of time. Common effects include:

Structural Damage

- Deterioration of the steel reinforcements in walls or ceilings.

- Rotting timber framing and joinery.

- Plaster, paint and finishes degeneration.

Health & Air Quality Issues

- The growth of moulds and mildew, which emits spores that are toxic to the respiratory system.

- Sticky smells of wet stuff.

- Air not comfortable, sticky, and unpleasant to use.

- Legionnaires disease as a result of moist, damp area.

Aesthetic & Equipment Damage

- Bemoaned or water-spotted glazing.

- Condensation through the back of mirrors or ornamental panels.

- Corrosion of fittings, lamps and air vents.

- Wetness causes electrical hazards in fittings.

Indications of a Condensation Issue

- Continued fogging on the windows or skylights.

- Scaling paint or plaster of Paris.

- Ceilings and corners have mould or black spots.

- Damp odours.

- Scab on screws, hinges or duct work.

- Sticky humid air, despite heating.

- Legionnaires disease Cough, fever, shortness of breath, and muscle aches.

When any of these arise, then it is time to review your humidity control system.

There are three Condensation Control Pillars

The combination of dehumidification, ventilation, and thermal design is the most effective that is to be supported at the very first level of design.

Dehumidification Systems

A dehumidifier is the core of any climate control system of an indoor pool. It extracts the moisture in the air and keeps the relative humidity in equilibrium.

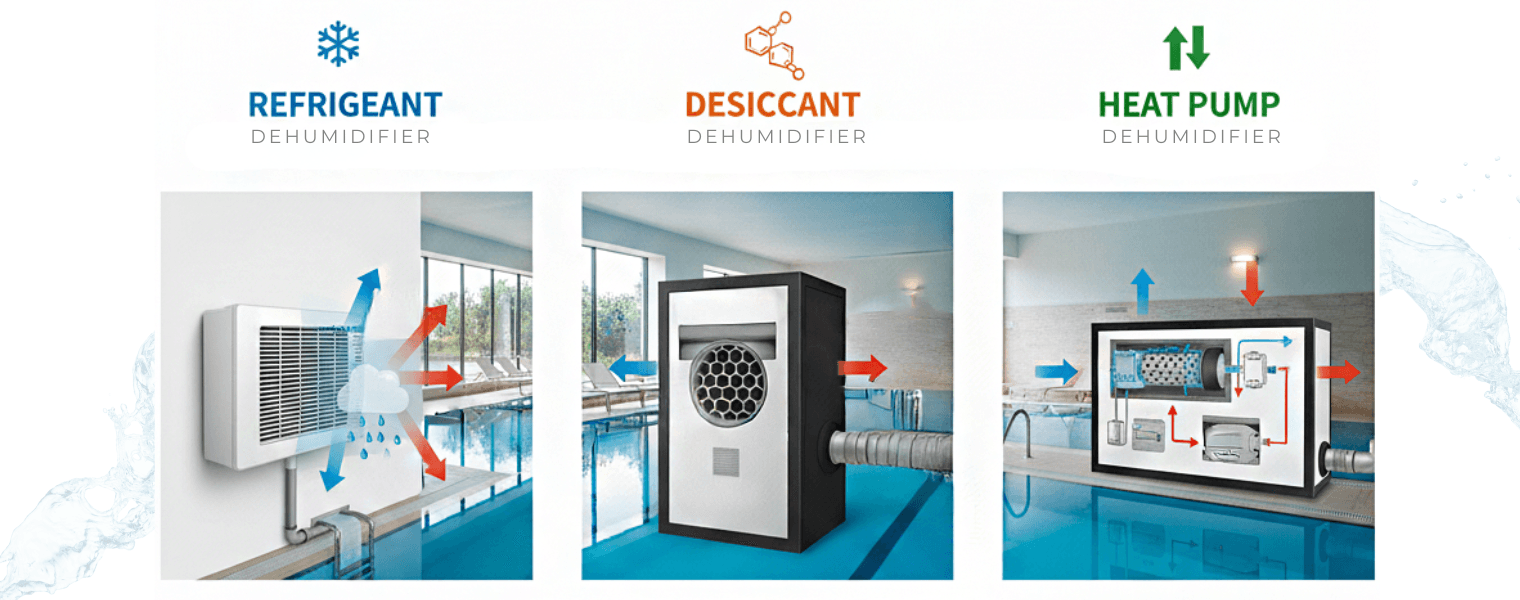

Kinds of Pool Room Dehumidifiers.

1. Condensing (Refrigerant) Dehumidifiers.

- The most widespread of residential pools.

- Work When air is cooled, moisture condenses on coils and later heated air is discharged back in.

- Efficient in temperatures that are above 15 degrees.

2. Desiccant Dehumidifiers

- Take a moisture absorbing substance (silica gel or lithium chloride).

- More suitable in cooler or basement areas where the temperature of the air is less.

- Usually, more costly and accurate.

3. Heat Pump Dehumidifiers

- Blend dehumidification and air heating.

- Use the moisture extraction to recover the latent heat and use it to heat the air or pool water.

- Very efficient in terms of energy and perfect in the UK homes when they want to spend less on running the house.

Sizing & Specification

- The system should be corresponding to the surface area of the pool, temperature of water, and level of use.

- A small unit will not be able to maintain a proper level of humidity, a big one will use much energy.

- Certainly, air change rate, use of a pool cover, and ambient design temperature must be considered in calculations.

Ducted and Wall-Mounted Systems.

Ducted (Plant Room) Units: silent, out of sight and may be combined with air heating and cooling. Best suited in luxury homes and business pools.

Wall-Mounted Units: Small and affordable to small pools.

Ventilation and Air Distribution.

Airflow design must be used to support dehumidification to get rid of stagnant, damp air and inject conditioned, drier air.

1. Supply and Return Air Design

- Warm and dry air should be supplied in the areas near the windows and cold surfaces to avoid the formation of a condensation in these areas.

- Pull out damp air on both sides of the room and have it circulate equally.

- Never short-circuit (always supply air directly to return vents).

2. Air Change Rates

- Normal: 4-6 air exchanges per hour in personal pools, 6-8 in commercial.

- More when the pool water is warmer or in a spa.

3. HVAC Systems Integration.

The new systems are integrated ventilation, heating, and dehumidification in a single smart unit.

Features may include:

- Humidity sensors and thermostats.

- Efficiency in variable speed fans.

- Heat recovery ventilation (HRV) to recover heat in the exhaust air.

- Dampers to balance the air pressure are automated.

4. Fresh Air Introduction

It is recommended to introduce a small percentage (5-10%) of fresh outdoor air which would help in controlling the odours and keep the air quality intact but preheated, to avoid cooling the room.

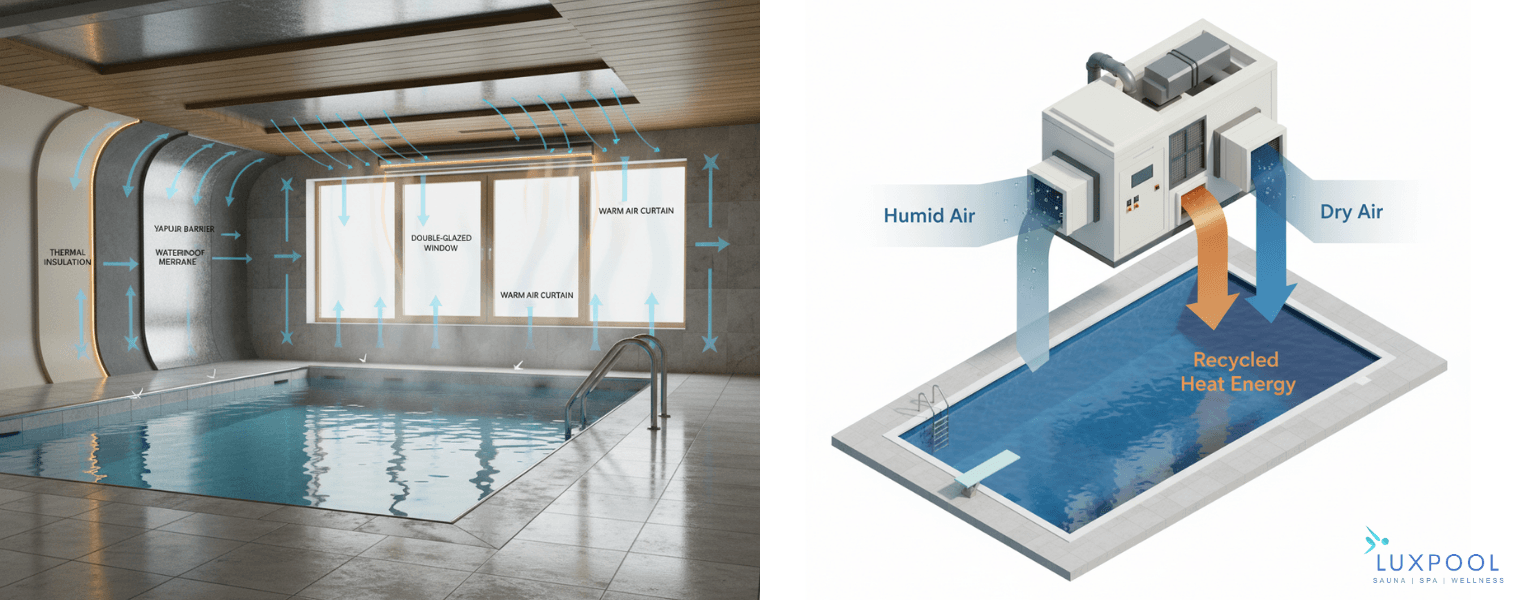

Thermal Design & Insulation

The avoidance of condensation is also made through the consideration of ensuring that the inside surfaces remain over the dew point temperature.

Key Strategies

- Wall, ceiling and glazing insulation of high grade to minimize cold spots.

- The window frames, doors and structure are thermally separated to prevent cold bridging.

- Construction of warm deck roof (insulation on top of the vapour control layer).

- Windows in pool room to be double or triple glazed.

- Heated air curtain around doors or glass walls to prevent condensation.

Vapour Barriers

The use of a continuous vapour control layer (VCL) at the back of finishes eliminates the movement of moisture into the building fabric.

- Should be fixed on warm side of insulation.

- Should be closed at all the junctions to prevent the occurrence of condensation behind walls.

Control of Air and Water Temperature

An important regulation of indoor pool:

Maintain air temperature 1-2°C above the water temperature.

For example:

- Water: 28°C

- Air: 29-30°C

This equilibrium retards evaporation and humidity. When the air is too cold, the water quickly evaporates off the surface of the pool flooding the dehumidifier.

It also has temperature control, which makes things comfortable to the user and energy saving.

Application of Pool Covers in Humidity Control

Evaporation is greatly decreased by the use of pool covers when the pool is not in use.

- Evaporation reduction: up to 70-80%

- Energy conservation: do not need so much heating.

- Reduction in the load of the system: light work of dehumidifiers.

Types include:

- Automatic slatted covers (motorised and built in).

- Manual but effective thermal floating covers.

- Bubble blankets to use in cost effective systems.

It is always advisable to cover the pool when not in use or overnight.

Monitoring, Maintenance and Control Systems

Automated Controls

The latest dehumidifiers are connected to smart controllers, which measure:

- Relative humidity

- Air & water temperature

- Energy usage

These are able to control the fan speeds, heating and compressor cycles to ensure an ideal balance is maintained whilst maximising on the energy consumption.

Regular Maintenance

- Clean air filters and coils

- Inspect ducting for leaks

- Test humidity sensors and thermostats.

- To maintain efficiency, service units on a yearly basis.

An unchecked system soon becomes unproductive and humidity once more increases.

Basement Pools Condensation: Special Consideration

Basement pools have special problems:

- Inadequate natural ventilation.

- Wall and floor cold retaining.

- Increased differentials in air pressure.

Solutions include:

- Full duct heat recovery dehumidification.

- All retaining walls thermally insulated.

- It must push the moisture out of the pool room, as opposed to inward.

- Structural walls and floors have waterproof membranes.

- Specialized plant area of HVAC/dehumidification equipment.

High-Humidity Environment Material and Finish

Use moist resistant, corrosive resistant materials:

- Fittings and handrails of stainless steel (316 grade).

- Waterproof plasterboard or cement board.

- Vapour-proof paints and finishes Epoxy paints and finishes.

- Tiles and waterproof adhesives that are non-porous.

- Timber cladding: UPVC, GRP or treated.

- Light fittings and ductwork which are resistant to corrosion.

Do not use untreated timber, mild steel or normal gypsum-based finishes around pool areas.

Dehumidification and Ventilation: Energy Efficiency

Solutions that are energy efficient are essential in saving on operations costs and sustainability.

Options include:

- Heat recovery units (HRV / ERV) recovering the heat of exhaust air.

- Reused recovered heat dehumidifiers.

- Demand ventilation (only in case of humidity increase)

- Thermal loss prevention insulated ducting.

- Air systems that are combined with heat exchangers on pool water.

Such systems are able to save up to 40 percent of the total energy used as compared to simple systems

Condensation Control during Design Stage

The most appropriate moment to deal with condensation is when the construction is in progress.

Design Coordination The following points are important design coordinating points.

- Early contact with HVAC and dehumidification specialists.

- Provide adequate ceiling and wall space to ductwork.

- Install position supply grilles around cold or glass surfaces.

- Plan conceal service paths and service access.

- Simulate airflow and temperature zones using 3D BIM or CAD drawings.

Luxpool incorporates all these factors in designing the pool so that the environment is beautiful, durable and comfortable over decades.

Conclusion: Condensation Control Best Practice

- Maintain a humidity of 50-60% relative.

- Keep air temperature 12°C higher than water temperature.

- Install a ducted or heat pump type dehumidifier of the right size.

- Design heat recovery ventilation.

- Seal and insulate all surfaces on the building with a vapour barrier.

- Evaporation should be reduced by using pool covers.

- Check and keep track of systems.

- Humidity control should be incorporated during design and not post construction.

How Luxpool Can Help

Luxpool are specialists in designing and constructing indoor and basement swimming pools which are both luxurious and functional.

Our engineers integrate:

- High-tech dehumidifying and ventilation,

- Smart humidity control,

- Architectural detail which forbids condensation, and damp, all, right at the beginning of the work.

You are planning a new indoor pool, changing a basement into a wellness space, or renovating an existing pool, we will make sure that your pool environment remains comfortable, efficient, and does not create any problem with condensation.

You can contact us at present to discuss your project or ask about the site consultation.

* Too busy to read? Watch the video for a brief overview of the blog’s key points *

FAQ’s

Not efficiently it temporarily alters humidity as well as leads to loss of heat. Mechanical ventilation is much better when it is controlled.

Home portable units do not have pool capacity. Always apply a special pool dehumidification system. Contact Luxpool to get most appropriate systems.

Half to two thirds of humidity (50-60% RH) to be comfortable, safe and preserve material.

Yes dehumidifiers take moisture and not stale air. Air flow should be balanced.

With a good design and equipment, it can be managed to the extent of being invisible or harmless.